![]()

|

|

|

![]()

![]() MANUAL(HTW-05-AN)

MANUAL(HTW-05-AN)

![]() MANUAL(HTW-05-LM)

MANUAL(HTW-05-LM)

¢Ã FEATURES |

- The operator can get welding effects on multi deposits and the OSCILLATOR does make the welding bead clean and uniformed. - It is a propet solution to get a good back bead in the thin circle welding, because weld penetration is thin at the center. - Since the welding pool and the arc in both sides is stable, the undercut and overlap are prevented to reduce the welding defects. - There are several weaving program to make the effects lie an old hands at welding. |

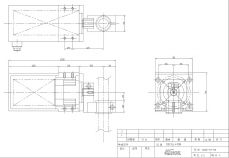

¢Ã SPEC |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

¢Ã SPEC |

||||||||||||||||||||

|

||||||||||||||||||||

* Note : The above mentioned

specification may be changed for better function |

¢Ã EFFICIENCY |

|

|

|

|

|

|

|

¢Ã THE PATTERN OF OPPRATING PROGRAM |

|||

|

|

|

|

|

|

|

|

![]()